Custom Digital Screen Printed Heat Transfers give decorators full color designs with a soft screen print feel, avoiding the plastic, shiny finish that many DTF prints have. They combine a screen-printed white base with digitally printed graphics, so your custom art keeps bright color, smooth gradients, and crisp detail while still sitting on the garment like a traditional screen printed design.

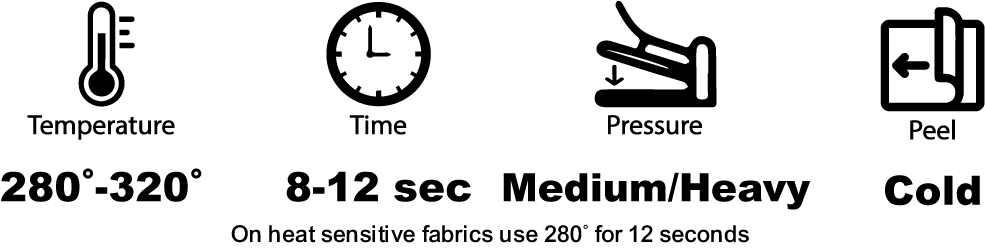

Because these hybrids are different from standard DTF, Custom Digital Screen Printed Heat Transfers do not have that thick film feeling, which helps the print stay softer, move with the fabric, and look more natural on cotton, polyester, blends, and heat sensitive materials. With a 12″ x 17.5″ max print size, free shipping, a 2–4 business day turnaround once artwork is ready, and clear artwork requirements, they’re an excellent option for brands and decorators that want full color without sacrificing comfort or visual quality.

Key Features

- Full color plastisol hybrid heat transfers

- Screen printed white base with digitally printed graphics

- Soft screen print feel without the plastic, shiny DTF-style finish

- Compared to DTF, avoids thick film feel for softer, more natural prints

- Vibrant full color for logos, photos, and detailed artwork

- Versatile: works on almost all fabrics including 100% cotton, polyester, blends, and heat sensitive fabrics

- Max print or gang size: 12″ x 17.5″

- Free shipping included

- Ships within 2–4 business days with print-ready artwork.

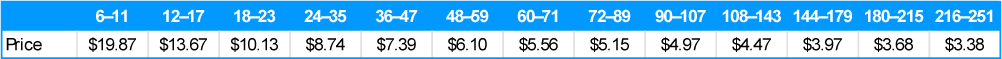

- 6 Minimum

Artwork Requirements ➔

Print Ready Basics

We print using CMYK so if the artwork provided is in RGB color it will produce a different color that won’t match what you see on screen.

There is no fading into the garment itself only fading/gradients into any other shape or color.

Your artwork prints as submitted, including size, spelling, and layout.

- Upload the file at the exact size you want it printed.

- If resizing is needed, include the exact width and height in your order notes.

- Artwork is uploaded in the correct orientation and not mirrored.

- Backgrounds are transparent unless a background is intended to print.

Preferred File Types

Vector artwork produces the cleanest edges and most consistent results.

Preferred (Vector)

Also Accepted

For raster files, artwork is provided at 300 dpi at final print size.

Canva Users

If you design in Canva, export your file as PDF Print for best results.

Color Setup

General Purpose transfers are produced using spot colors.

- Use solid colors when possible.

- Only include white when white ink is intended to print.

- If your file colors do not match what you want printed, list the intended colors in the order notes.

Minimum Detail Requirements

To prevent small details from filling in or breaking, artwork meets these minimum tolerances.

- Minimum printed line thickness: 1 pt or 0.014 in

- Minimum negative space: 2 pt or 0.028 in

Artwork below these tolerances may print heavier, fill in, or lose detail.

Text Requirements

All text is converted before submission to prevent font issues.

- Illustrator: convert text to outlines

- Photoshop: convert text to shapes

Converted text is no longer editable as live text.

Effects and Fine Detail Notes

Screen printed transfers are best for clean, solid artwork.

- Gradients, fades, shadows, and transparency effects may not reproduce as intended.

- Thin strokes and tiny “holes” inside letters can close up if they fall under minimum tolerances.

Files Not Accepted

Files from Cricut design tools, Windows Paint, Apple Paintbrush, and similar generic programs often do not separate cleanly for screen printing and may not be usable as submitted.

If anything is questionable, the fastest path is sending the best file available and including the intended print size.

Shipping & Turnaround ➔

vector-ready artwork are produced in 2–4 business days.

Orders with non-vector artwork usually add one extra business day. If the file is low quality or the artwork is complex, turnaround can take longer.

Multi-color orders and higher quantities may also require additional production time.

Shipping From New Jersey

Order Cutoff Time

Cutoff is Monday–Friday at 1:00 PM ET. Orders placed after 1:00 PM ET or on weekends begin processing the next business day.